Why On-Demand 3D Printing is a Game-Changer for Engineers

The Evolution of 3D Printing

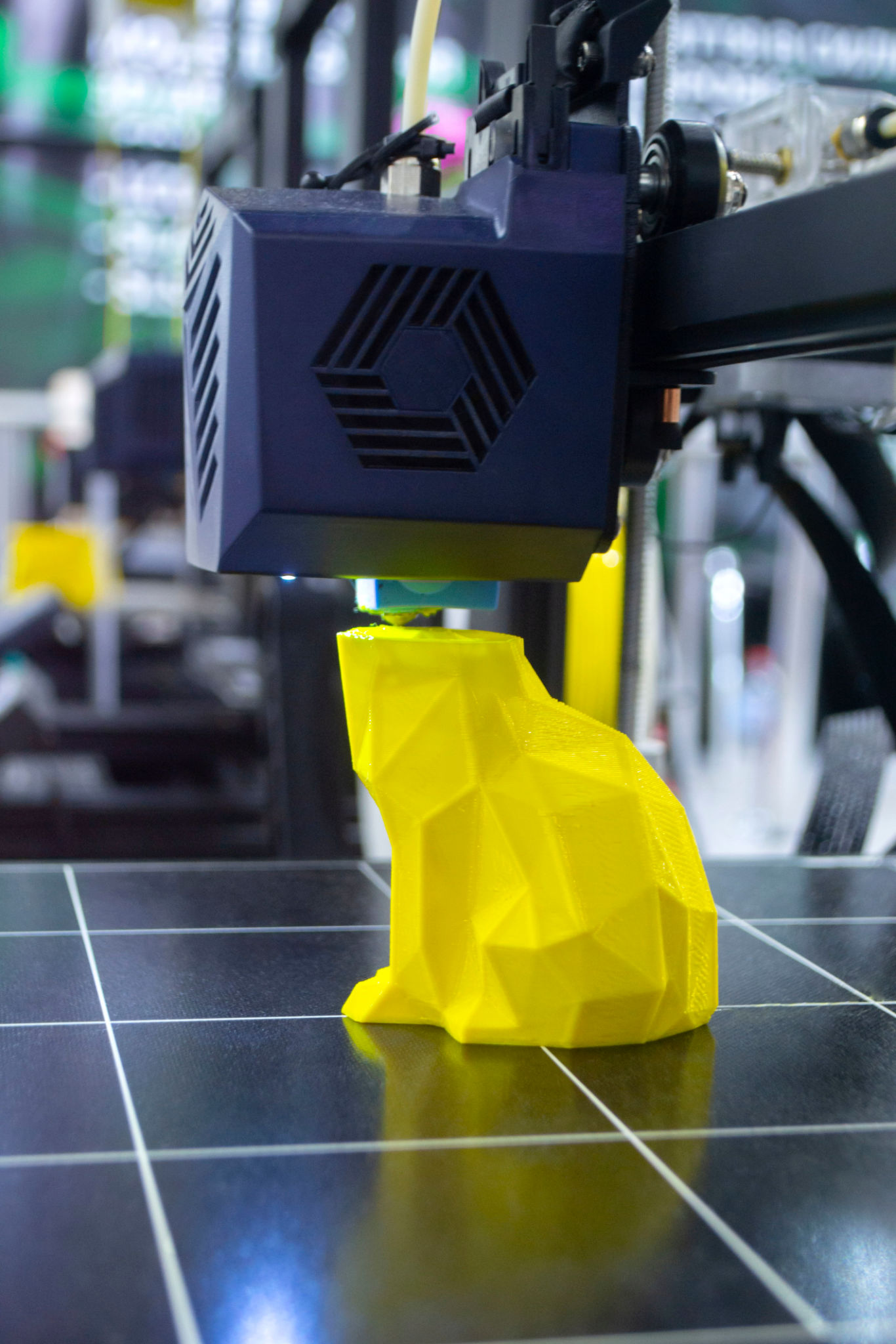

The advent of 3D printing has revolutionized various industries, and engineering is at the forefront of this transformation. Originally, 3D printing was a resource-intensive process, accessible only to large corporations. However, the emergence of on-demand 3D printing services has democratized access to this technology, making it a game-changer for engineers.

On-demand 3D printing allows engineers to rapidly prototype and test their designs without the need for significant capital investment in equipment. This flexibility enhances innovation and accelerates the product development cycle. Engineers can now focus on designing rather than worrying about the logistics of production.

Cost-Effectiveness and Accessibility

One of the most significant advantages of on-demand 3D printing is its cost-effectiveness. Traditional manufacturing methods often involve high costs associated with tooling, materials, and labor. In contrast, on-demand 3D printing eliminates many of these expenses, as engineers can order parts as needed without maintaining an inventory or investing in expensive machinery.

Moreover, the accessibility of these services has opened doors for smaller companies and individual engineers who may not have the resources to purchase and maintain their 3D printers. This democratization means that innovative ideas can be brought to life regardless of the size of the company or budget.

Speed and Efficiency

Speed is another crucial factor where on-demand 3D printing excels. The ability to produce prototypes quickly allows engineers to iterate their designs rapidly. This rapid prototyping is invaluable when working within tight deadlines or under pressure to bring a product to market swiftly.

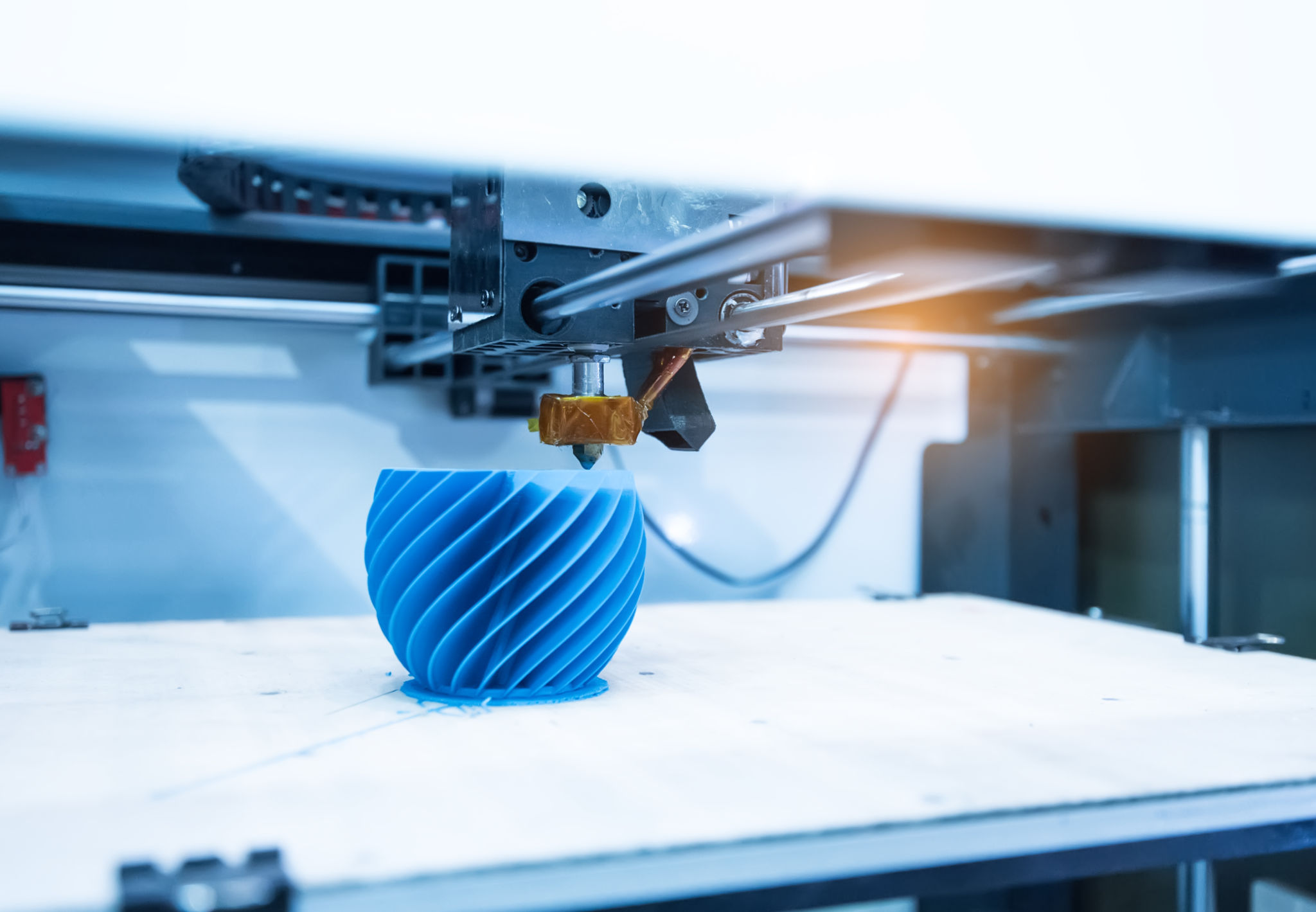

Additionally, on-demand 3D printing services often offer a wide range of materials and finishes, enabling engineers to choose the best option for their specific application. This variety enhances the efficiency of the design process by allowing immediate testing and refinement.

Customization and Personalization

On-demand 3D printing also offers unparalleled customization capabilities. Engineers can easily modify designs to suit specific requirements without incurring additional costs or delays. This level of personalization is particularly beneficial in industries like aerospace, automotive, and healthcare, where bespoke solutions are often required.

The ability to customize extends beyond the design phase; engineers can select materials that best meet their needs, whether they require lightweight components for aerospace applications or biocompatible materials for medical devices.

Sustainability and Innovation

As sustainability becomes increasingly important across industries, on-demand 3D printing offers a more environmentally friendly alternative to traditional manufacturing. By reducing material waste and minimizing transportation emissions through localized production, this technology supports greener engineering practices.

Furthermore, the innovation potential of on-demand 3D printing is vast. Engineers can experiment with complex geometries and structures that would be impossible or prohibitively expensive using conventional methods. This freedom fosters creativity and pushes the boundaries of what is possible in engineering design.

The Future of Engineering

The shift toward on-demand 3D printing is more than just a trend; it's a fundamental change in how engineers approach design and production. As technology continues to advance, we can expect even greater integration of these services into engineering workflows, enhancing both efficiency and innovation.

For engineers looking to stay ahead in a competitive landscape, embracing on-demand 3D printing is not just an option—it's a necessity. By leveraging these services, engineers can focus on what they do best: solving problems and creating groundbreaking solutions.