The Impact of 3D Printing on Automation in Manufacturing

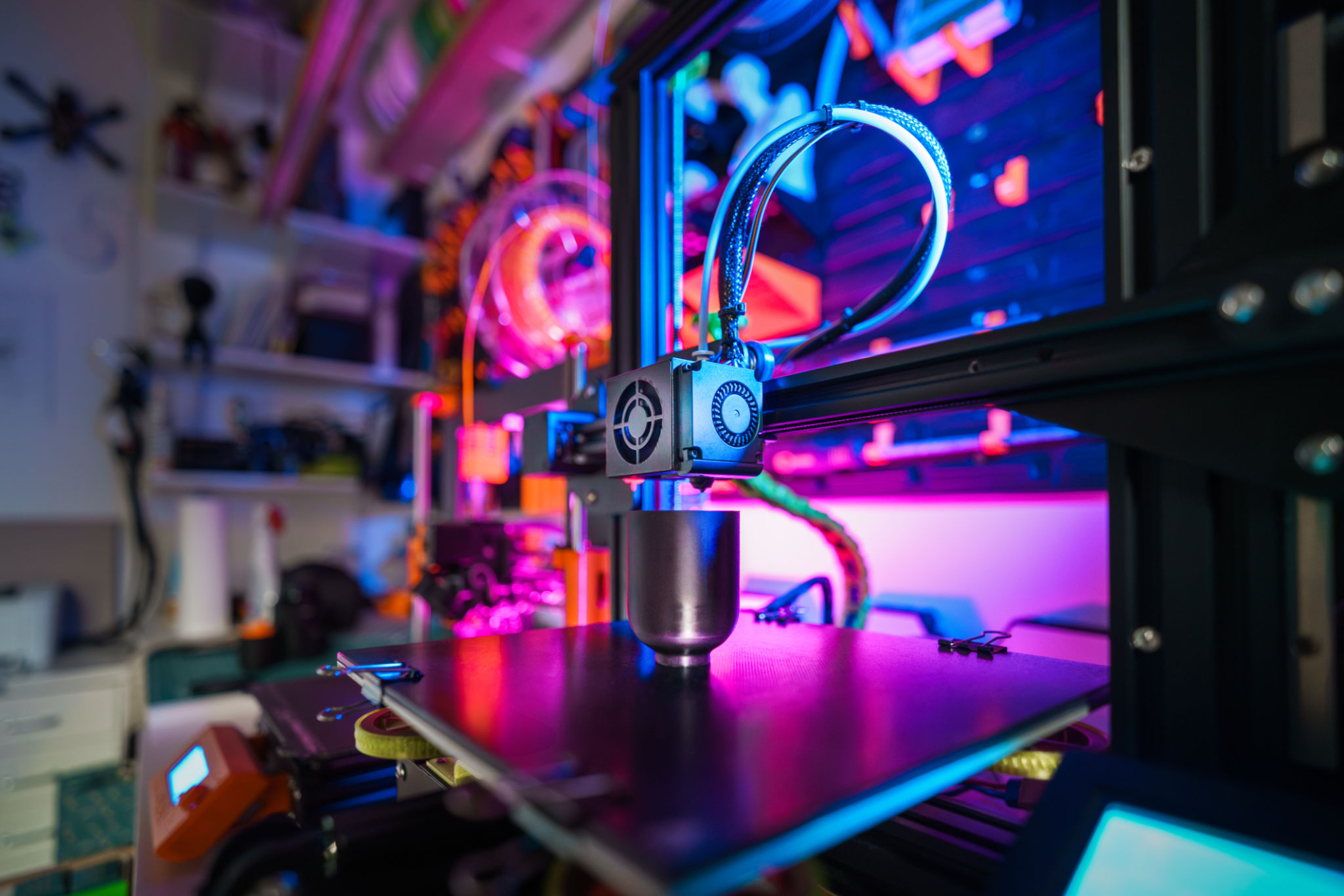

Revolutionizing Manufacturing with 3D Printing

In the past decade, 3D printing has emerged as a transformative force in the manufacturing industry. By enabling the rapid production of complex parts, it has significantly altered how manufacturers approach design and production processes. As this technology continues to evolve, its integration with automation systems is reshaping the entire manufacturing landscape.

The fusion of 3D printing with automation brings about unprecedented levels of efficiency and customization. This synergy not only accelerates production times but also reduces waste and costs, thereby offering a competitive edge to manufacturers who adopt these technologies.

Enhancing Flexibility and Customization

One of the most significant advantages of 3D printing in manufacturing is its ability to produce highly customized products without the need for extensive retooling. This flexibility allows manufacturers to quickly adapt to market demands and customer preferences, which is particularly beneficial in industries such as aerospace, automotive, and healthcare.

With 3D printing, manufacturers can create complex geometries and intricate designs that were previously impossible or highly expensive to produce using traditional methods. This capability opens up new possibilities for innovation, allowing companies to explore novel product designs and applications.

Streamlining Production Processes

The integration of 3D printing with automated systems streamlines production by reducing the number of steps involved in manufacturing. This combination minimizes human intervention, leading to faster production cycles and fewer errors. Automated 3D printing systems can operate continuously, further boosting productivity and efficiency.

Moreover, by reducing the reliance on traditional supply chains, 3D printing enables manufacturers to produce parts on-demand and closer to their point of use. This localized production capability lowers shipping costs, reduces lead times, and enhances supply chain resilience.

Reducing Waste and Environmental Impact

Traditional manufacturing often involves subtractive processes, where material is removed from a larger block to create the desired shape, resulting in significant waste. In contrast, 3D printing is an additive process, building objects layer by layer with minimal material wastage.

This efficiency not only reduces costs but also aligns with sustainability goals by minimizing the environmental impact of manufacturing operations. As industries increasingly prioritize eco-friendly practices, 3D printing offers a viable solution for reducing the carbon footprint associated with production.

Challenges and Future Prospects

Despite its numerous advantages, the adoption of 3D printing in manufacturing is not without challenges. High initial costs, limited material options, and the need for specialized skills can pose barriers to entry for some companies. However, ongoing advancements in technology and materials are gradually overcoming these hurdles.

Looking ahead, the continued integration of 3D printing with automation systems promises to further revolutionize manufacturing. As innovations in areas such as artificial intelligence and machine learning enhance these technologies' capabilities, we can expect even greater efficiency, customization, and sustainability in manufacturing processes.

In conclusion, the impact of 3D printing on automation in manufacturing is profound and far-reaching. By embracing this transformative technology, manufacturers can unlock new levels of productivity and innovation, paving the way for a more efficient and sustainable future.