The Future of On-Demand 3D Printing for Engineers

The Evolution of On-Demand 3D Printing

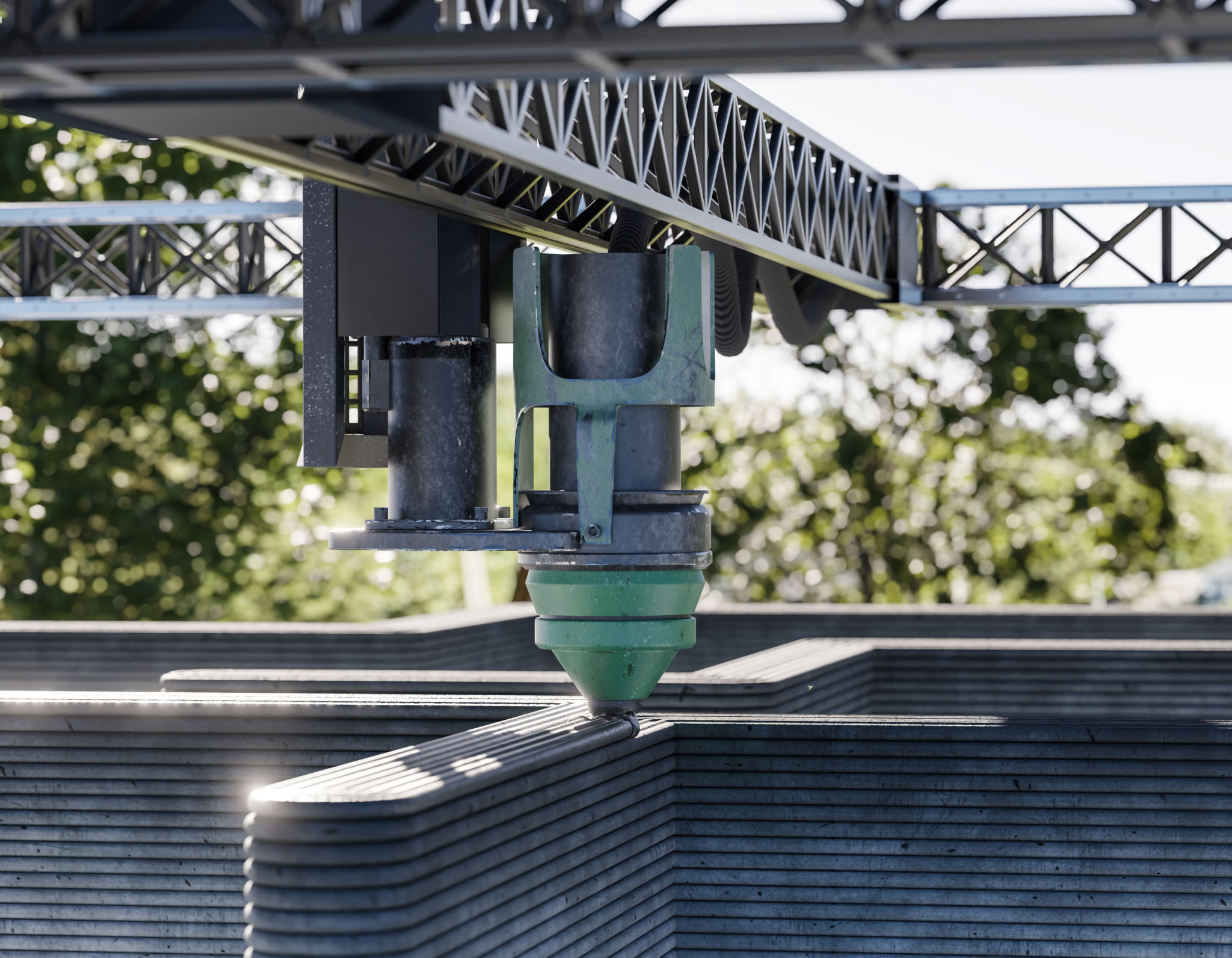

In recent years, on-demand 3D printing has transformed from a niche technology into a mainstream solution for engineers across various industries. This evolution is reshaping how products are designed, prototyped, and manufactured. With the advent of more sophisticated materials and improved printer capabilities, engineers now have unprecedented flexibility and speed in their design processes. As the technology continues to evolve, it's crucial to understand its future implications for engineering.

Revolutionizing Prototyping

One of the most significant impacts of on-demand 3D printing is in prototyping. Engineers can now create prototypes rapidly without the need for extensive tooling or production lines. This reduction in time and cost allows for greater experimentation and innovation. With the ability to print complex geometries that were previously impossible or cost-prohibitive, engineers are pushing the boundaries of what's achievable in product design.

Moreover, the iterative nature of design becomes more dynamic with 3D printing. Engineers can quickly test and refine their ideas, leading to better-performing products. This agility is particularly beneficial in industries such as aerospace and automotive, where precision and performance are paramount.

Expanding Material Options

The range of materials available for 3D printing has expanded significantly. Engineers can now choose from a variety of plastics, metals, ceramics, and even composite materials. This diversity enables the creation of parts that meet specific mechanical and thermal properties, making 3D printing a viable option for more applications than ever before.

As material technology advances, we can expect to see even more specialized materials that offer enhanced durability, flexibility, or conductivity. This will open up new possibilities for engineers in fields ranging from medical devices to consumer electronics.

Customization and Personalization

On-demand 3D printing is particularly well-suited for customization and personalization. Unlike traditional manufacturing methods, which often require large production runs to be cost-effective, 3D printing allows for the economical production of small batches or even single, unique items. This capability is transforming industries where customized solutions are critical, such as healthcare and fashion.

For engineers, this means the ability to tailor parts to specific requirements without incurring significant additional costs. As a result, products can be optimized for individual use cases, improving performance and user satisfaction.

The Impact on Supply Chains

On-demand 3D printing is also poised to disrupt traditional supply chains. By enabling localized production, companies can reduce their reliance on global manufacturing hubs and minimize shipping costs and times. This shift can lead to more resilient supply chains that are less vulnerable to disruptions.

- Reduced lead times

- Lower inventory costs

- Enhanced ability to respond to market demands quickly

Looking Forward

The future of on-demand 3D printing for engineers looks promising. As the technology matures, we can expect further improvements in speed, precision, and material capabilities. These advancements will continue to enhance the efficiency of engineering processes and expand the range of applications across industries.

Ultimately, the integration of on-demand 3D printing into engineering practices will not only drive innovation but also reshape how products are developed and brought to market. Embracing this technology will be crucial for engineers looking to remain competitive in an increasingly digital world.