SLS 3D Printing: Revolutionizing Short-Run Manufacturing Processes

Introduction to SLS 3D Printing

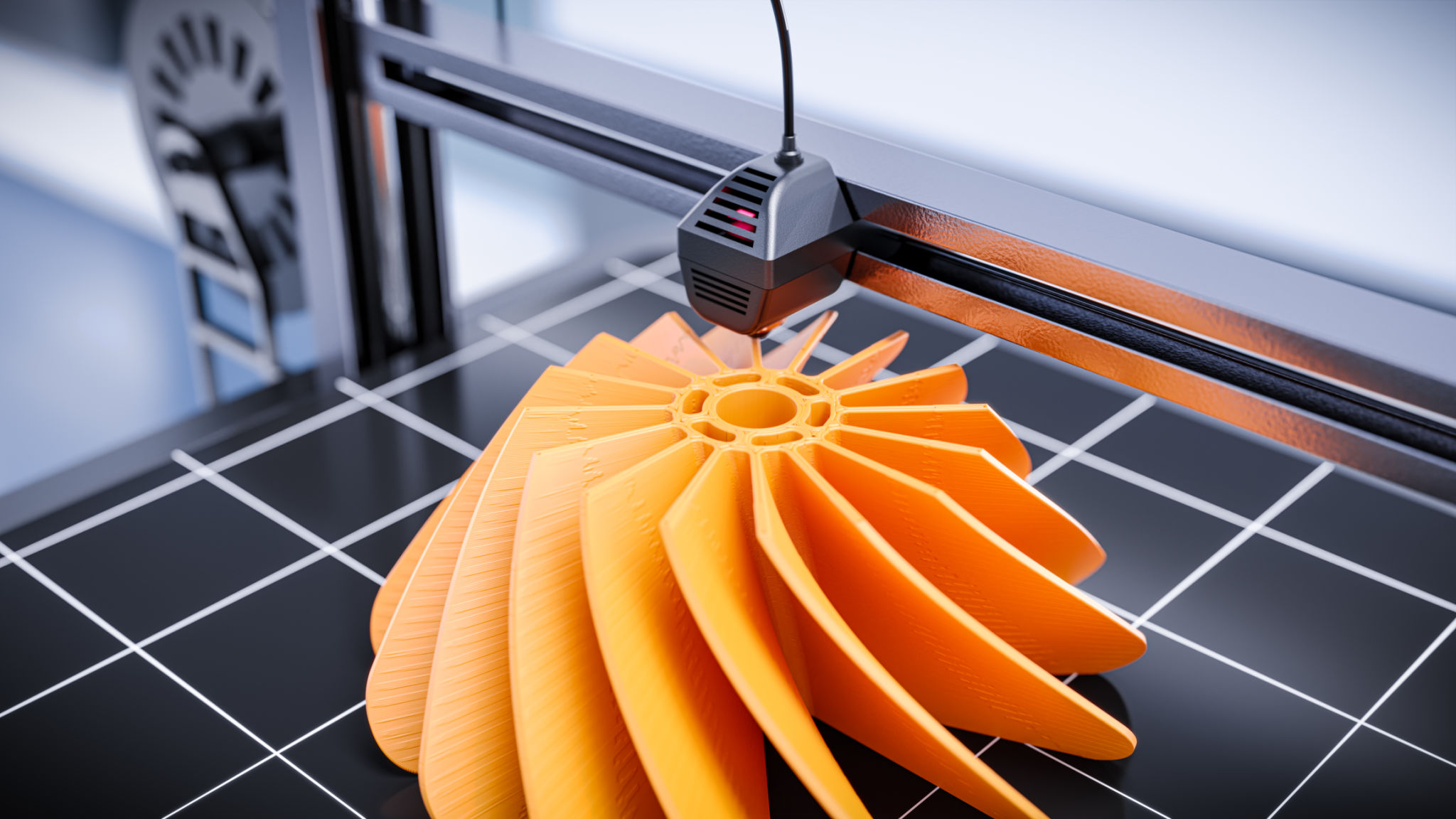

Selective Laser Sintering (SLS) 3D printing is rapidly transforming the landscape of short-run manufacturing. By using a high-powered laser to fuse small particles of polymer powder, SLS 3D printing allows for the creation of complex and durable parts without the need for traditional tooling. This innovative technology is particularly beneficial for industries that require rapid prototyping and short production runs.

The Benefits of SLS 3D Printing

One of the most significant advantages of SLS 3D printing is its ability to produce parts with intricate geometries that would be impossible or cost-prohibitive with conventional manufacturing methods. This capability opens up new possibilities for designers and engineers, enabling them to create innovative products that push the boundaries of design.

Another key benefit is the reduction in material waste. Since SLS 3D printing uses only the material necessary to create a part, it is a more sustainable option compared to traditional subtractive manufacturing processes. Additionally, unused powder can often be recycled and reused in subsequent builds, further minimizing waste.

Applications in Various Industries

SLS 3D printing is making waves across various sectors. In the aerospace industry, for example, companies are utilizing this technology to produce lightweight components that maintain structural integrity. The ability to create complex parts without additional assembly steps also reduces production time and costs.

The medical field is another sector benefitting from SLS 3D printing. Custom prosthetics and implants can be manufactured quickly and tailored to the unique anatomy of each patient. This level of customization is essential for improving patient outcomes and comfort.

Challenges and Considerations

Despite its many advantages, SLS 3D printing does come with certain challenges. The initial investment in equipment can be significant, which may be a barrier for some small businesses. Furthermore, the process requires specialized knowledge and expertise to ensure optimal results.

Another consideration is the quality of the final product. While SLS produces strong and durable parts, achieving a smooth surface finish may require additional post-processing steps. Businesses must weigh these factors when deciding whether to adopt SLS 3D printing for their manufacturing needs.

The Future of Short-Run Manufacturing

As technology continues to advance, the potential applications for SLS 3D printing in short-run manufacturing are expected to grow. Innovations in materials and processes are likely to enhance the capabilities of SLS printers, making them more accessible and efficient for a wider range of industries.

Ultimately, SLS 3D printing represents a significant shift in how products are designed and manufactured. By embracing this technology, businesses can stay ahead of the competition and meet the ever-evolving demands of their customers.