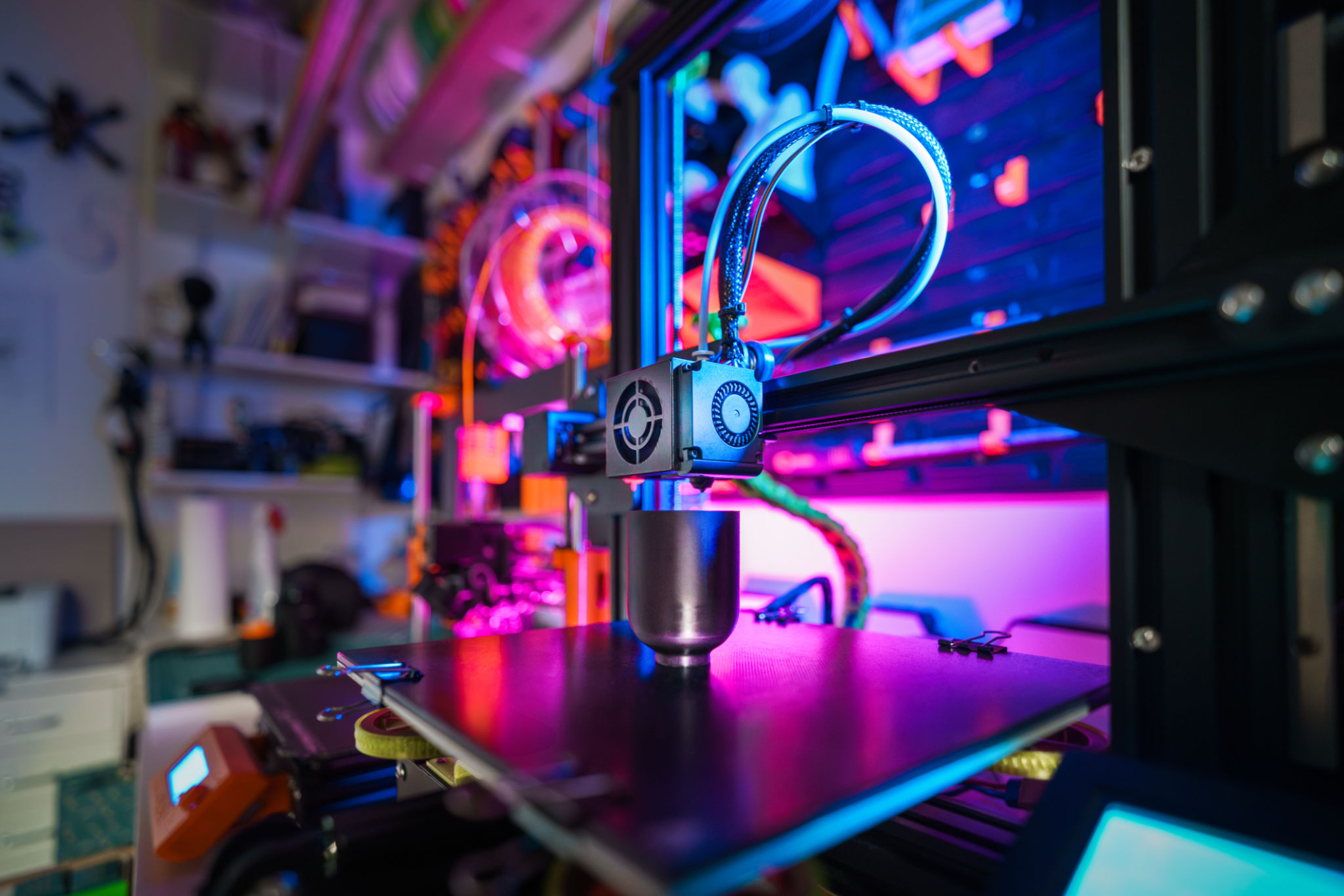

Preparing for Seasonal Demand: How 3D Printing Can Help Manufacturers

Understanding Seasonal Demand

Seasonal demand can pose significant challenges for manufacturers, as it requires rapid scaling up of production to meet peak periods. Whether it's holiday sales, back-to-school rushes, or summer vacation spikes, businesses must be prepared to respond swiftly and efficiently. Failure to do so can lead to lost sales opportunities and dissatisfied customers.

Traditionally, manufacturers have relied on methods such as stockpiling inventory or increasing labor hours to cope with seasonal demand. However, these strategies can be costly and inefficient. This is where 3D printing technology comes into play as a game-changer for managing seasonal production demands.

The Flexibility of 3D Printing

One of the greatest advantages of 3D printing is its flexibility. Unlike traditional manufacturing methods that require costly molds or tooling, 3D printing allows manufacturers to quickly and easily adjust their production lines to accommodate changes in demand. This means that companies can produce exactly what they need when they need it, reducing waste and storage costs.

Moreover, 3D printing enables rapid prototyping and iteration, allowing manufacturers to test new designs or products quickly. This agility can be particularly beneficial in adapting to market trends or launching limited edition products during peak seasons.

Cost-Effective Production

3D printing can also significantly reduce production costs. By minimizing material waste and eliminating the need for expensive molds, manufacturers can enjoy lower overheads. This cost-effectiveness makes it easier for businesses to experiment with new product lines and take risks during high-demand periods without the fear of substantial financial loss.

Speeding Up Production

In addition to being flexible and cost-effective, 3D printing is also fast. Traditional manufacturing processes can take weeks or even months to ramp up production, particularly if new tooling is required. In contrast, 3D printing can significantly shorten production times, enabling manufacturers to respond almost immediately to sudden spikes in demand.

This speed is crucial during seasonal peaks when time is of the essence. By integrating 3D printing into their production strategies, manufacturers can ensure they are always ready to meet customer needs without delay.

Customization and Personalization

Another advantage of 3D printing is its ability to facilitate customization and personalization. As consumer preferences increasingly shift towards personalized products, manufacturers can use 3D printing to offer bespoke items without the need for large minimum orders.

This capability not only enhances customer satisfaction but also opens up new revenue streams during seasonal sales events. Businesses can capitalize on trends by offering limited edition or personalized products that appeal directly to their target audience.

Conclusion: Embracing the Future

As manufacturers prepare for seasonal demand, embracing 3D printing technology can provide a competitive edge. The flexibility, cost-effectiveness, speed, and customization options offered by 3D printing make it an invaluable tool in meeting the challenges of fluctuating market demands.

By adopting this innovative approach, businesses can not only meet seasonal demand more efficiently but also enhance their overall production capabilities. In an ever-evolving market landscape, staying ahead of the curve with technologies like 3D printing is essential for success.