How On-Demand 3D Printing Empowers Engineers: A Comprehensive Guide

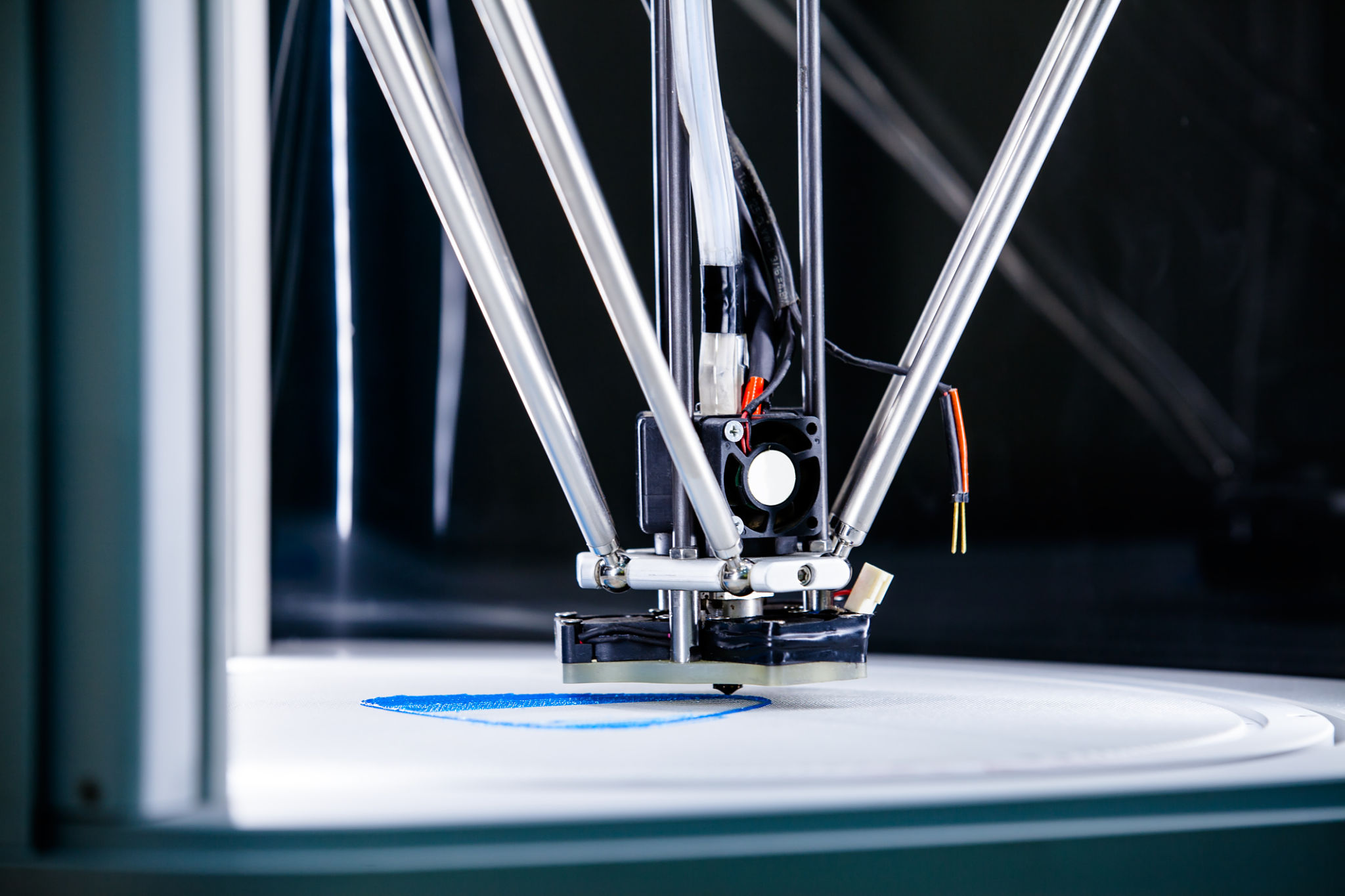

Introduction to On-Demand 3D Printing

In recent years, the field of engineering has experienced a significant transformation with the advent of on-demand 3D printing. This technology offers engineers unprecedented flexibility, efficiency, and innovation. By enabling rapid prototyping and customization, 3D printing is reshaping the way engineers design and produce components.

Speed and Efficiency in Prototyping

The ability to quickly produce prototypes is one of the most significant advantages of on-demand 3D printing. Traditionally, creating a prototype could take weeks or even months. With 3D printing, engineers can now produce a prototype within hours or days, allowing for faster iteration and refinement of designs.

This rapid prototyping capability helps engineers to test concepts and identify potential design flaws early in the development process, reducing the time and cost associated with bringing a product to market. As a result, companies can respond more quickly to market demands and technological advancements.

Customization and Flexibility

An additional benefit of on-demand 3D printing is the level of customization it offers. Engineers can easily modify designs to create bespoke solutions tailored to specific applications or customer requirements. This flexibility is particularly valuable in industries such as aerospace, automotive, and healthcare, where custom components are often required.

Furthermore, the ability to make quick adjustments without incurring significant costs enables engineers to experiment with new ideas and innovative designs, fostering a culture of creativity and exploration within engineering teams.

Cost-Effectiveness and Resource Efficiency

On-demand 3D printing can also lead to substantial cost savings for engineering projects. Traditional manufacturing processes often require expensive tooling and setup costs, which can be prohibitive for small production runs or custom parts. In contrast, 3D printing eliminates the need for such investments, making it a cost-effective solution for producing small batches or one-off components.

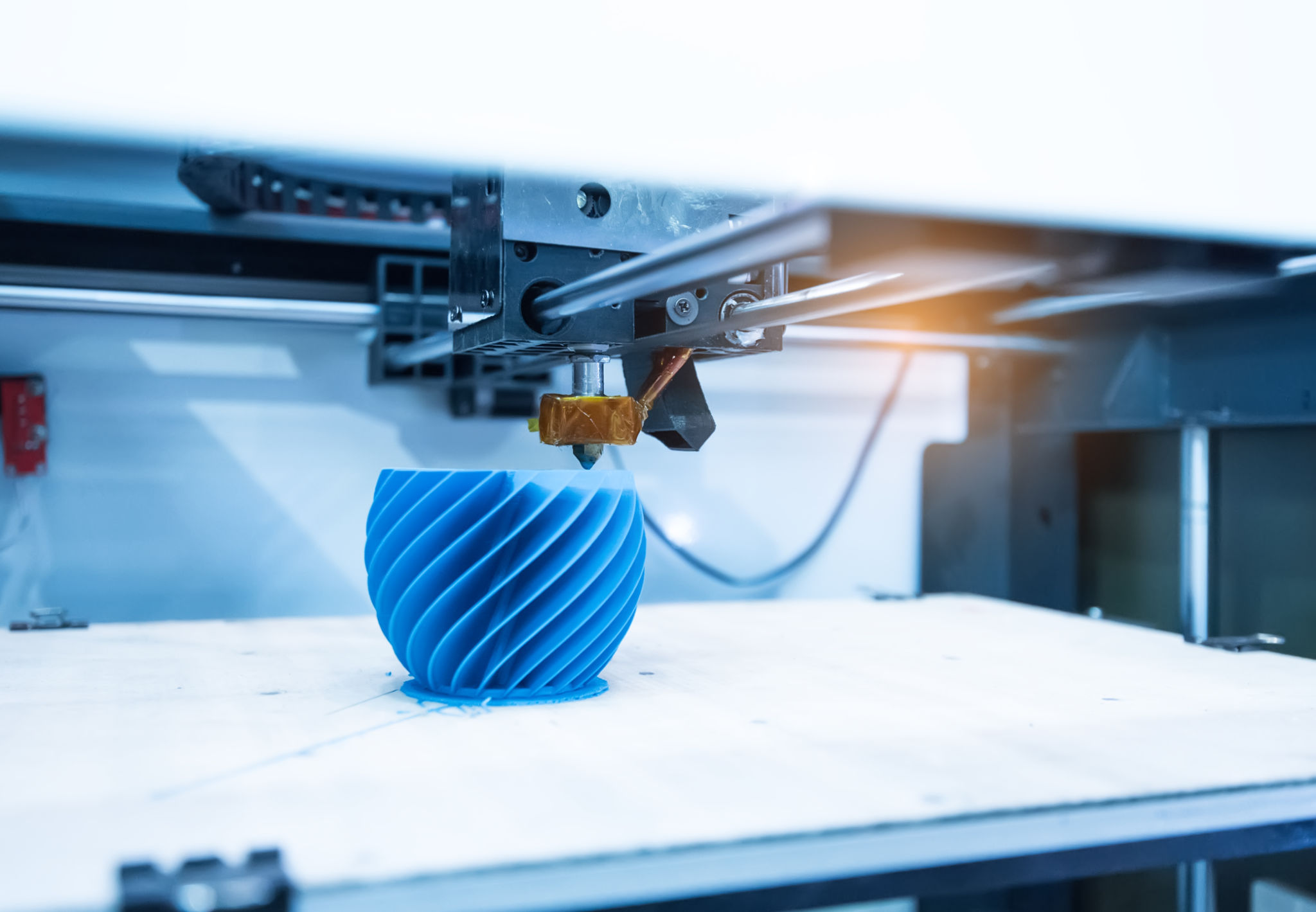

Moreover, 3D printing is an additive manufacturing process, meaning it builds components layer by layer. This approach minimizes material waste compared to subtractive methods like machining, where material is removed from a solid block. As a result, 3D printing not only saves money but also promotes sustainability by reducing resource consumption.

Empowering Innovation in Engineering Design

The freedom offered by on-demand 3D printing empowers engineers to push the boundaries of design. Complex geometries that are difficult or impossible to achieve through traditional manufacturing can be realized with ease using 3D printing. This capability opens up new possibilities for creating lightweight structures, intricate internal features, and optimized component designs.

By enabling engineers to explore these new design possibilities, 3D printing fosters innovation and drives the development of cutting-edge solutions across various industries.

Conclusion

On-demand 3D printing is revolutionizing the engineering landscape by providing fast, flexible, and cost-effective solutions for prototyping and production. By empowering engineers with the tools they need to innovate and create customized solutions, this technology is paving the way for a new era of engineering excellence. As more companies embrace 3D printing, its impact on engineering will continue to grow, driving progress and inspiring the next generation of engineers.