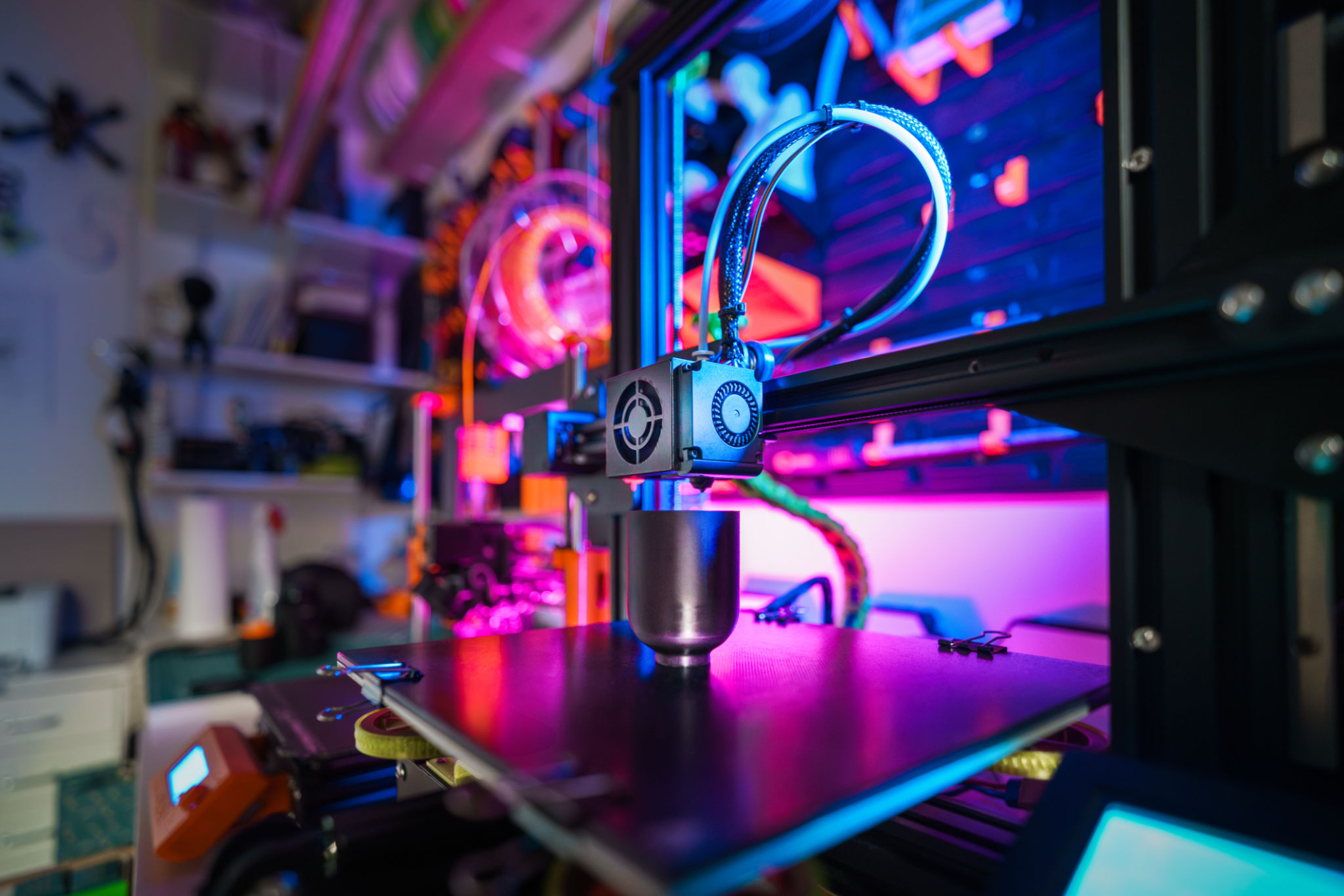

How 3D Printing Revolutionizes Fixture and Jig Prototyping

Introduction to 3D Printing in Manufacturing

In recent years, 3D printing has transitioned from a niche technology to a mainstream tool in various industries. One of the most significant areas where it has made an impact is in the prototyping of fixtures and jigs. These essential manufacturing tools, used to hold, support, and align parts during production, have traditionally been costly and time-consuming to produce. With 3D printing, however, companies can now create these tools with unprecedented speed and customization.

Speed and Efficiency

Rapid Prototyping

One of the standout benefits of 3D printing is its ability to rapidly produce prototypes. In the past, developing a prototype for a fixture or jig could take weeks, involving complex processes such as machining or molding. Now, with 3D printing, designs can be transformed into physical objects in just a matter of days or even hours. This acceleration allows manufacturers to quickly test and iterate on their designs.

Cost Reduction

Traditional methods of manufacturing fixtures and jigs often involve high costs due to material waste and complex labor. 3D printing significantly reduces these expenses. By using additive manufacturing techniques, material is only used where necessary, minimizing waste. Moreover, the ability to print on-demand reduces the need for large inventories, cutting storage costs and reducing financial risk.

Customization and Flexibility

Design Freedom

3D printing offers unparalleled flexibility in design. Engineers can create complex geometries that would be impossible or prohibitively expensive with traditional techniques. This design freedom means that fixtures and jigs can be tailored precisely to the specifications needed for any given task, enhancing performance and efficiency on the production line.

Iterative Design Process

The iterative nature of 3D printing allows for continuous improvement. As testing reveals flaws or areas for enhancement, modifications can be made swiftly without the need for retooling entire production processes. This agility improves the overall quality of the tools produced, leading to better outcomes in manufacturing operations.

Sustainability and Material Innovation

Eco-Friendly Practices

Beyond efficiency and customization, 3D printing also contributes to more sustainable manufacturing practices. The reduction in material waste is a significant factor, but so is the ability to use eco-friendly materials. Many 3D printers now support biodegradable plastics or recycled materials, aligning with broader environmental goals.

Emerging Materials

The innovation in materials compatible with 3D printing is another exciting development. High-strength polymers and composite materials are becoming more available, allowing for the production of durable yet lightweight fixtures and jigs. These materials open new possibilities for applications that require strength without added bulk.

Conclusion

The revolution brought by 3D printing in fixture and jig prototyping is undeniable. Its influence extends beyond mere cost savings or efficiency gains; it fundamentally transforms how manufacturers approach design and production. As technology continues to evolve, it promises even greater advancements, driving innovation and sustainability across industries.