From Prototype to Production: Streamlining Manufacturing with SLS 3D Printing

Introduction to SLS 3D Printing

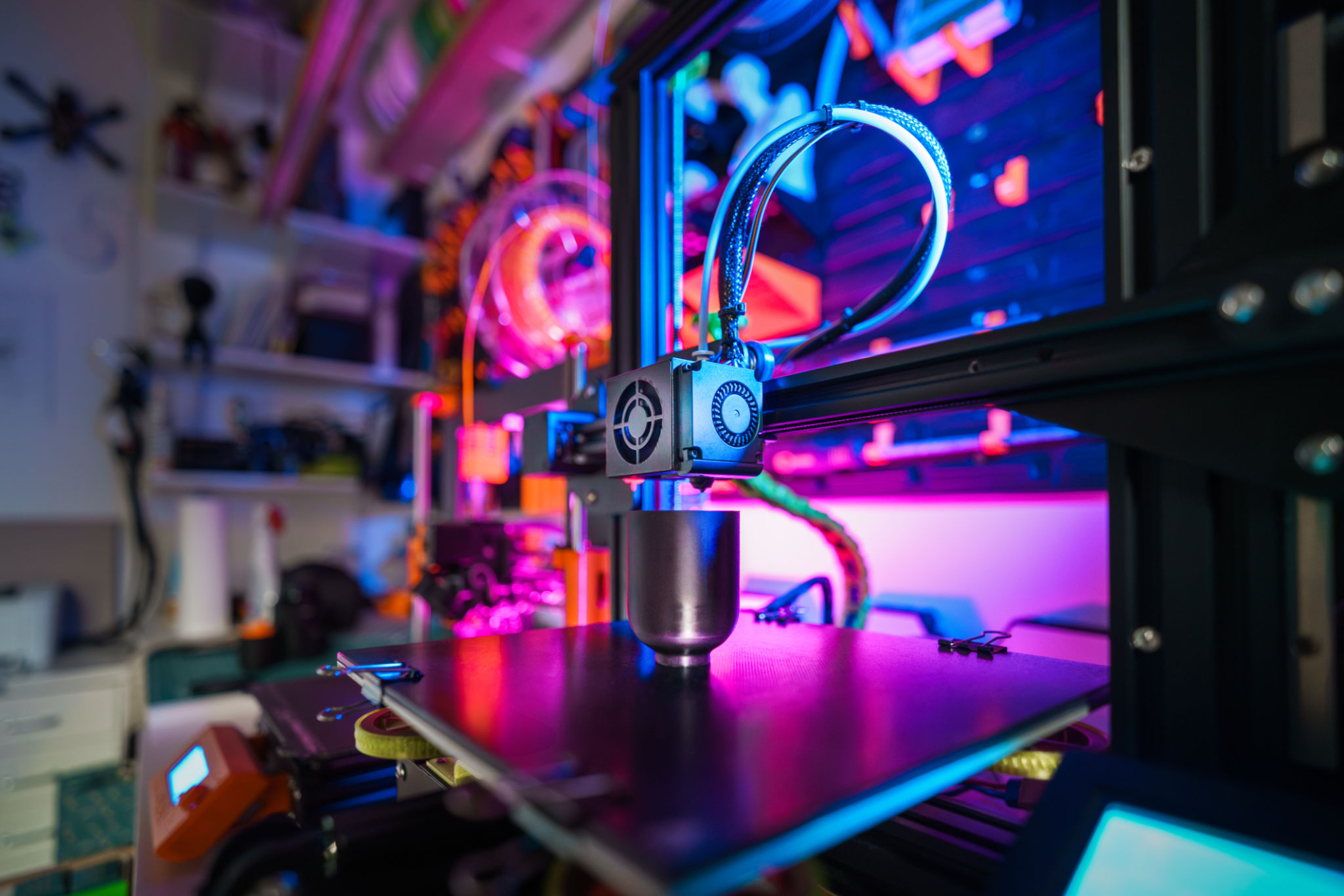

Selective Laser Sintering (SLS) 3D printing is revolutionizing the manufacturing industry by offering a seamless transition from prototype to production. This advanced technology allows manufacturers to create complex geometries and functional parts with precision and efficiency. As the demand for rapid prototyping and customized production grows, SLS 3D printing stands out as a versatile solution.

Understanding the SLS Process

The SLS process involves using a high-powered laser to fuse powdered material layer by layer, creating a solid structure. Unlike other 3D printing techniques, SLS does not require support structures, making it ideal for intricate designs. This method is particularly advantageous for producing strong, durable parts from a variety of materials, including plastics and metals.

The ability to work with different materials enables manufacturers to select the most suitable option for their specific application, ensuring optimal performance and cost-efficiency. SLS 3D printing is transforming how industries approach design and production.

Benefits of SLS in Manufacturing

SLS 3D printing offers numerous benefits that streamline the manufacturing process. Some of the key advantages include:

- Design Freedom: SLS allows for complex geometries that are difficult or impossible to achieve with traditional methods.

- Cost-Efficiency: By reducing material waste and eliminating the need for tooling, SLS lowers production costs.

- Speed: Rapid prototyping and shorter lead times accelerate product development cycles.

Prototyping to Production

One of the most significant challenges in manufacturing is bridging the gap between prototyping and mass production. With SLS 3D printing, this transition becomes seamless. Manufacturers can quickly iterate on designs, test functionality, and make necessary adjustments without the high costs associated with traditional prototyping methods.

Once a prototype is finalized, scaling up to production is straightforward with SLS. The same 3D printing setup used for prototyping can be employed for full-scale manufacturing, ensuring consistency and quality across all units.

Applications Across Industries

The versatility of SLS 3D printing makes it applicable across various industries. In the automotive sector, it is used for producing lightweight parts that enhance vehicle performance. The medical industry benefits from custom implants and prosthetics tailored to individual patients' needs. Consumer electronics manufacturers leverage SLS for creating intricate components that fit compactly within devices.

Challenges and Considerations

While SLS 3D printing offers numerous advantages, there are challenges to consider. Post-processing can be labor-intensive, requiring careful removal of excess powder and surface finishing. Additionally, the initial investment in SLS equipment and training can be substantial for some manufacturers.

However, as technology advances and costs decrease, these barriers are becoming less significant. Companies that invest in SLS 3D printing are positioning themselves at the forefront of innovation, ready to capitalize on its long-term benefits.

The Future of Manufacturing with SLS

The future of manufacturing is undeniably linked to advancements in 3D printing technologies like SLS. As industries continue to demand faster, more flexible production methods, SLS is poised to meet these needs effectively. It offers a sustainable approach to manufacturing by reducing waste and optimizing resource usage.

In conclusion, transitioning from prototype to production with SLS 3D printing is transforming the manufacturing landscape. Its ability to produce complex, high-quality parts quickly and cost-effectively makes it an invaluable asset for any forward-thinking company.