Frequently Asked Questions About 3D Printing with SLS Nylon PA12

What is SLS Nylon PA12?

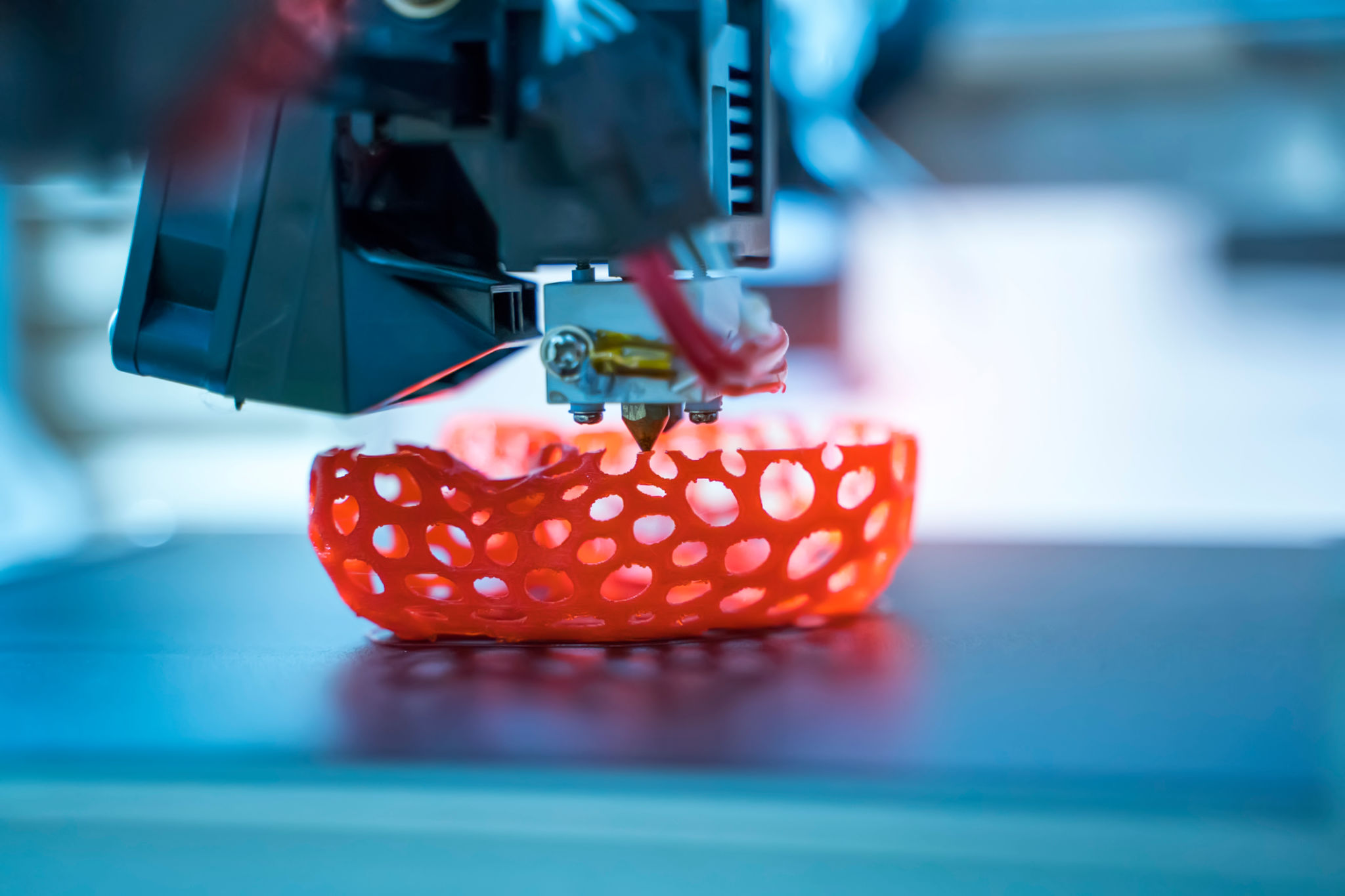

SLS Nylon PA12 is a type of plastic used in 3D printing, specifically in Selective Laser Sintering (SLS) technology. This material is known for its durability, flexibility, and resistance to chemicals and impact. It is widely used in various industries, from automotive to healthcare, due to its excellent mechanical properties and smooth surface finish.

One of the main advantages of SLS Nylon PA12 is that it does not require support structures during the printing process. This allows for more complex geometries and intricate designs, making it a popular choice for prototyping and production parts alike.

How Does SLS Technology Work?

SLS technology involves using a high-powered laser to selectively fuse powdered material layer by layer. The process starts with a thin layer of nylon powder spread across the build platform. The laser then traces the cross-section of the part, sintering the powder together. After each layer is completed, the build platform lowers slightly, and a new layer of powder is applied.

This process is repeated until the entire object is created. Once the print is complete, the part is allowed to cool down before being removed from the surrounding powder. The excess powder can be recycled and reused for future prints, making SLS a cost-effective and sustainable option.

What Are the Benefits of Using Nylon PA12 in 3D Printing?

Nylon PA12 offers several benefits that make it an ideal choice for 3D printing:

- Durability: Parts printed with Nylon PA12 are highly durable and resistant to wear and tear.

- Chemical Resistance: This material can withstand exposure to a wide range of chemicals, making it suitable for industrial applications.

- Flexibility: Nylon PA12 provides good flexibility, allowing for parts that require some degree of bending or movement.

The material's properties make it perfect for applications that demand reliability and performance under stress. From automotive components to medical devices, Nylon PA12 is a trusted material choice.

What Are Some Common Applications for SLS Nylon PA12?

SLS Nylon PA12 is used in a diverse range of industries due to its versatility. Some common applications include:

- Automotive Parts: Used for manufacturing complex components like air intake systems and brackets.

- Consumer Goods: Ideal for producing durable and lightweight products such as eyewear and sports equipment.

- Medical Devices: Utilized in creating custom prosthetics and orthotics due to its biocompatibility.

The ability to produce functional prototypes and end-use parts quickly makes SLS Nylon PA12 an invaluable resource in product development.

How Does SLS Nylon PA12 Compare to Other 3D Printing Materials?

SLS Nylon PA12 stands out among other 3D printing materials due to its unique balance of properties. While materials like PLA and ABS are often used for low-cost prototyping, Nylon PA12 offers superior strength and durability, making it more suitable for functional parts.

Compared to other nylon materials, such as Nylon 11, PA12 generally provides better dimensional stability and lower water absorption, making it more reliable in various environmental conditions.

What Are the Limitations of SLS Nylon PA12?

Despite its numerous advantages, SLS Nylon PA12 does have some limitations. One notable drawback is the surface finish, which can be slightly rougher compared to other printing technologies like SLA. However, post-processing techniques such as tumbling or polishing can be employed to improve the finish.

Additionally, SLS systems can be expensive, which might not be feasible for small businesses or hobbyists. However, service bureaus offer access to SLS technology without the need for upfront investment in equipment.

How Can I Get Started with SLS Nylon PA12?

If you're interested in exploring the benefits of SLS Nylon PA12 for your projects, there are several approaches you can take. Partnering with a professional 3D printing service can provide you access to high-quality SLS machines without significant investment. Alternatively, investing in an SLS printer might be an option if your production needs justify the cost.

Consider starting with a small project to familiarize yourself with the material properties and process intricacies. This will help you effectively utilize Nylon PA12 in your specific applications.