Debunking Common Myths About 3D Printing Services

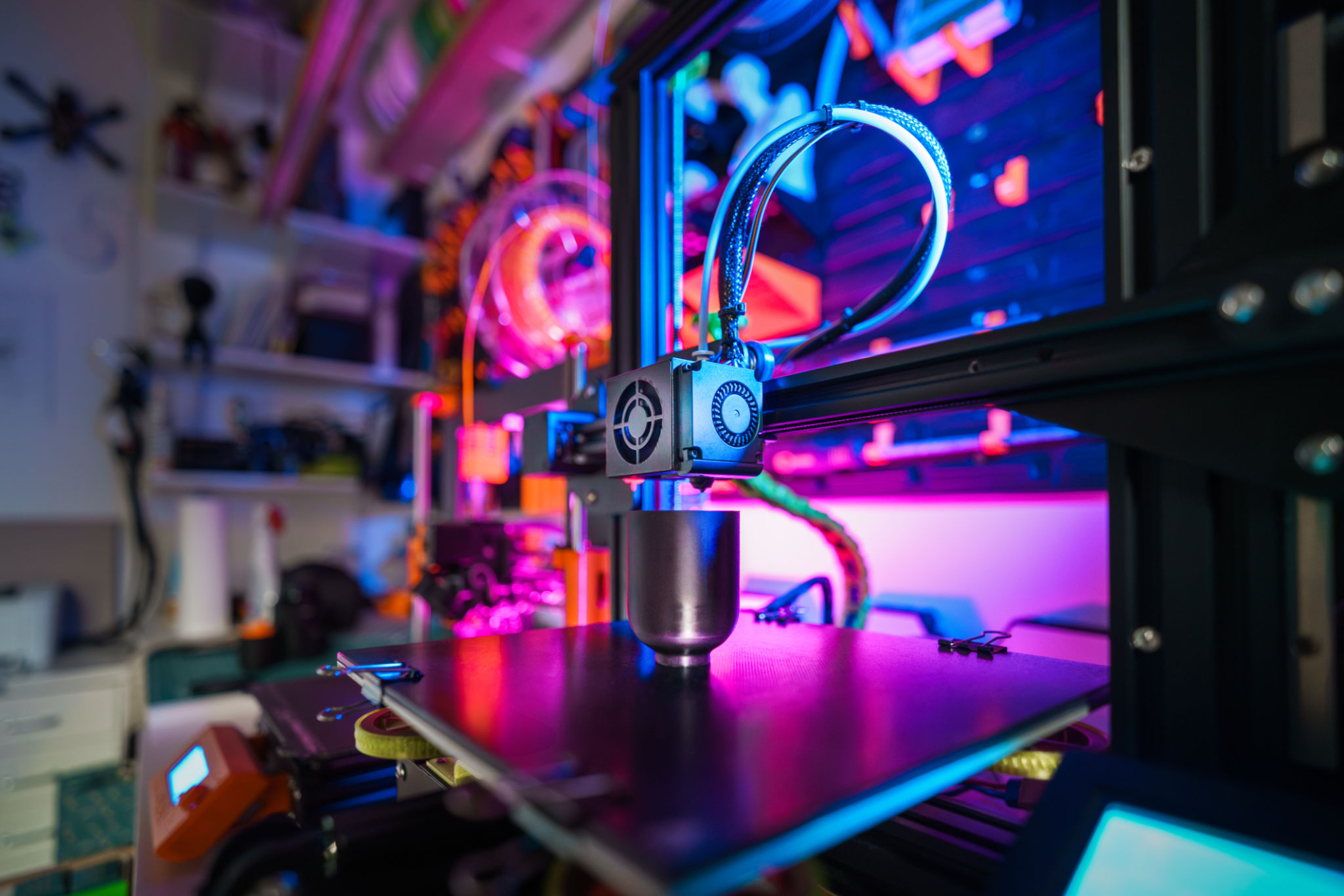

Understanding 3D Printing Services

3D printing has become a revolutionary force in a variety of industries, from healthcare to automotive. However, despite its growing popularity, many misconceptions persist about what 3D printing services can and cannot do. It's time to set the record straight and debunk some common myths surrounding this innovative technology.

Myth 1: 3D Printing Is Only for Prototyping

One of the most prevalent myths is that 3D printing is solely for prototyping purposes. While it's true that 3D printing is excellent for creating prototypes quickly and cost-effectively, its applications extend far beyond that. Today, 3D printing is used for end-use products across various sectors, including aerospace, fashion, and even food production.

Industries are leveraging the flexibility and precision of 3D printing to produce customized parts that would be otherwise impossible with traditional manufacturing methods. As a result, 3D printing has become an integral part of production lines.

Myth 2: 3D Printing Is Not Cost-Effective

Another common misconception is that 3D printing is too expensive to be practical for most businesses. While some high-end machines can be costly, the overall affordability of 3D printing has improved significantly over the years. For small to medium-sized production runs, 3D printing can actually save money by reducing waste and eliminating the need for expensive molds or tooling.

Moreover, the ability to create complex geometries without additional costs allows for more efficient designs that can lead to further cost savings in materials and production time.

Myth 3: 3D Printed Items Are Low Quality

The perception that 3D printed objects lack quality and durability stems from early iterations of the technology. However, advances in materials and printing techniques have dramatically improved the quality of 3D printed items. Today, it's possible to produce parts with strength and precision comparable to those made using traditional methods.

Many industries now rely on 3D printing for high-quality components that meet strict regulatory and safety standards, proving the technology's capability to deliver reliable results.

Myth 4: 3D Printing Is Slow

Speed is often cited as a limitation of 3D printing, but this myth doesn't hold up under scrutiny. While some complex parts may take longer to print, modern 3D printers are increasingly faster and more efficient. Additionally, the ability to print multiple parts simultaneously can drastically reduce production times.

As technologies continue to advance, we can expect even faster turnaround times, making 3D printing an even more attractive option for manufacturers looking to streamline their operations.

The Future of 3D Printing Services

As we continue to debunk myths about 3D printing services, it's clear that this technology offers immense potential and versatility. From rapid prototyping to producing high-quality end-use products, 3D printing is transforming industries worldwide. By understanding its true capabilities, businesses can fully harness the power of this innovative manufacturing process.

It's essential to stay informed about the latest developments in 3D printing to capitalize on its benefits effectively. As more organizations embrace this technology, we can anticipate even greater innovations in the years to come.